Vacuum brazing of stainless steel

Jetzt Originaltickets für Stainless Steel direkt bei Eventim bestellen! Alle Termine & Tickets für Veranstaltungen bei Eventim: Jetzt einfach & sicher bestellen.

Brazing Furnaces Straight & Humpback Design Abbott Furnace

1. Gas carburising and carbonitriding 2. Neutral hardening and annealing 3. Gas nitriding and nitrocarburising 4. Brazing of metals 5. Low pressure carburising and high pressure gas quenching 6. Sintering of steels Preface. This expert edition is part of a series on process application technology and know-how available from Linde Gas.

Alumina Base Vacuum Brazing Furnace Stainless Steel Chamber For Aluminum Alloy

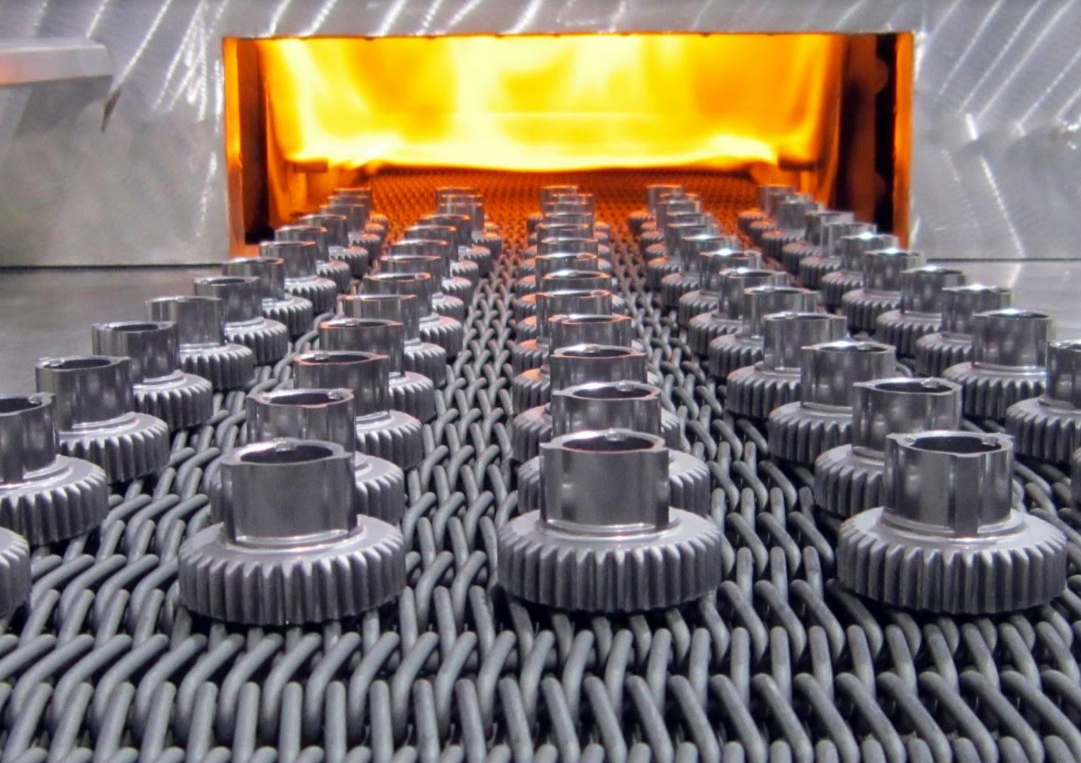

Furnace brazing is a semi-automated process used to join metal components with a dissimilar, lower melting filler metal. It allows designs of one or multi-joint assemblies to be joined by a reproducible metallurgical bond. One of the most common forms of furnace brazing is accomplished in a vacuum furnace.

Stainless steel copper titanium alloy vacuum high temperature brazing furnace VHB334 Buy high

Furnace brazing provides the highest quality joints and is the only technique well adapted to complex assemblies, ceramic-to-metal bonding, large/massive parts, or highly reactive materials because assemblies are heated uniformly and multiple joints are brazed simultaneously.

Brazing of Stainless Steel Joints Induction Brazing UltraFlex Power

Stainless steel copper brazing - SIMUWU Vacuum Furnace Email: [email protected] | Tel : +86-21-50878190 | 24 hours online : +8613916614261 CN | RU Toggle navigation Home About Us Product Heat treatment equipments Brazing Solutions Powder Metalluragy Equipments Electrical Equipments Solution Applications Our Projects PDF Download News

What Is Furnace Brazing And How Does It Work? The Fan Angel

The dew point is used to determine the amount of water vapor in the system at given conditions. The dew point is the temperature at which an amount of water vapor in the system will saturate the atmosphere. The typical dew point required for brazing stainless steel joints in 100% Hydrogen is -50º F.

High Temperature Vacuum Brazing Furnace For Stainless Steel 12 324L Capacity

Furnace brazing can also be used to join metals that are difficult to weld, such as aluminum, copper, and stainless steel. Inert Atmosphere. Furnace brazing is typically performed in an inert atmosphere, such as nitrogen or argon. This prevents the formation of oxides on the surface of the metal, which can weaken the joint.

induction heating High Frequency Brazing Stainless Steel Fittings

What Is Brazing? Brazing joins metals by flowing a thin capillary thickness layer of non-ferrous filler metal into the space between them. Bonding results from the intimate contact produced by the dissolution of a small amount of base metal into the molten filler metal, without fusion of the base metal.

Induction Brazing Stainless Steel Tubes With Induction Heater

There are six fundamentals of brazing that every brazer should follow to ensure consistent and repeatable joint quality, strength, hermeticity, and reliability.

Brazing Fundamentals Abbott Furnace Company Brazing Furnaces

Through the process of vacuum furnace brazing or vacuum diffusion bonding, we can join the alloys used in your applications. It's a low-distortion method that results in ultra-strong parts. Both a clean assembly room and a high-purity brazing furnace with excellent temperature control are crucial to the process. We've got that covered.

Brazing Copper to Stainless Steel YouTube

brazing furnace is used for the vacuum brazing of materials like non-ferrous metal, stainless steel, titanium alloy, high temperature alloy, cemented carbide, etc. Furnace brazing is a semi-automated process by which metal components are joined using a dissimilar lower filler metal.Furnace brazing allows design and manufacturing engineers to join simple or complex designs of one joint or multi.

Stainless steel copper titanium alloy vacuum high temperature brazing furnace VHB334 Buy high

Furnace brazing typically refers to the vacuum furnace batch-type brazing process. This involves a large "oven" where entire batches of parts are loaded into the furnace at one time. The furnace door is then closed, and the furnace is evacuated of all air then heated to the desired brazing temperature.

Furnace & Vacuum Brazing Services Brazing Aluminum Bluewater Thermal Solutions

Find out all of the information about the Bodycote product: furnace brazing . Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale.. stainless steel Applications automotive Certifications ISO 9001, ISO 14001, ISO/TS 16949, OHSAS 18001. Description. Furnace brazing is a semi.

Vacuum & Continuous Furnace Brazing Kepston Ltd

The types of brazing processes include torch brazing, furnace brazing in different atmospheres (dissociated ammonia, dry hydrogen, and vacuum atmosphere), dip brazing in salt bath, and high-energy-beam brazing. A complete list of the typical compositions and properties of standard brazing filler metals for brazing stainless steel is also provided.

Stainless steel copper titanium alloy vacuum high temperature brazing furnace VHB334 Buy high

Precision Furnace Brazing Discover the benefits of brazing with Altair, a new world of design possibilities and low costs. Vacuum & Furnace Brazing Services Altair Products Overview A global leader in LINACs, RF windows, electron guns, ion-pumps, and target assemblies. LINACs & Peripherals Overview Linear Accelerators

Round Fluxer Aluminium Radiator Continuous Brazing Furnace 304 Stainless Steel

Specializing in high temperature continuous furnace brazing and vacuum brazing. We are committed to promoting brazing through education and experience.. Bright Vacuum heat treating and furnace brazing of stainless steel and exotic metal alloys. > Learn More: Production Equipment: vacuum Heat Treating • Exothermic Atmosphere Brazing Furnaces